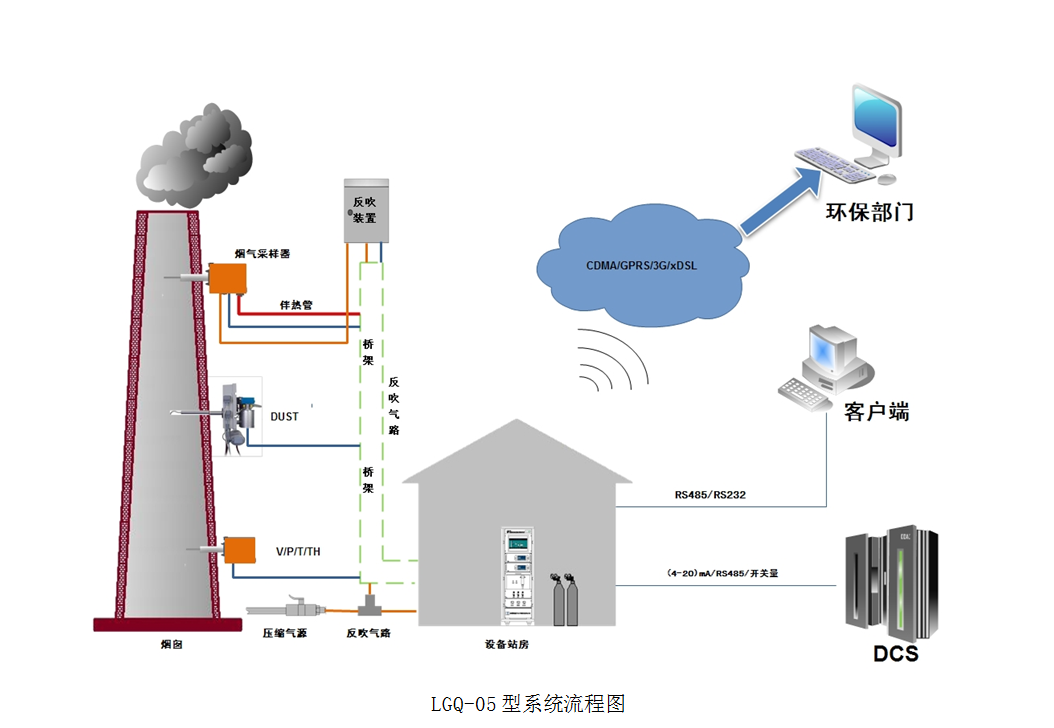

Product Introduction:

This product is designed for the online monitoring of ultra-low concentration flue gas and particulate matter from fixed pollution sources. It is primarily applied in sites with ultra-low emission concentration conditions. Using a direct sampling method, it measures the concentration of pollutants and particulates in the flue gas. Additionally, it directly measures parameters such as flue gas temperature, pressure, flow rate, and oxygen content. These data are sent to the data acquisition and processing subsystem, which calculates the flue gas pollutant emission rate and total emissions. Various parameters and graphs can be displayed and printed, and data can be transmitted to the enterprise pollution source monitoring center (central station) and environmental protection authorities via wired or wireless methods.

System Principle:

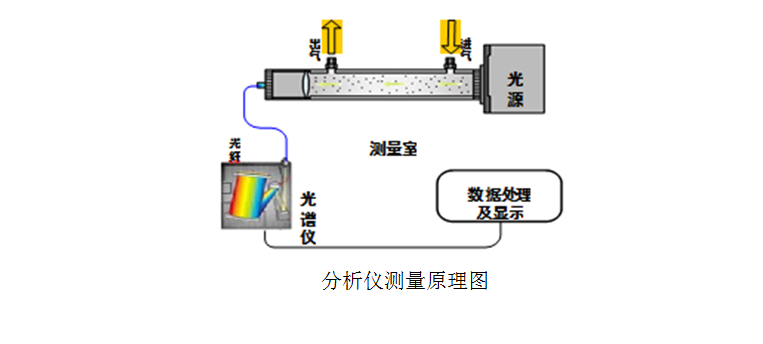

Gas Pollutant Monitoring Subsystem:

This subsystem employs Differential Optical Absorption Spectroscopy (DOAS) technology, enhanced by the analyzer's internal temperature control. The UV light emitted from the analyzer is collimated and directed through the measurement chamber. As the sample gas passes through, it absorbs UV energy at specific wavelengths. The absorbed light is then transmitted via optical fibers to the spectrometer, where a diffraction grating separates the light. A diode array detector converts the separated optical signals into electrical signals, allowing for continuous absorption spectrum data of the gas. Ultimately, this DOAS technique enables precise measurement of ultra-low concentrations of flue gas.

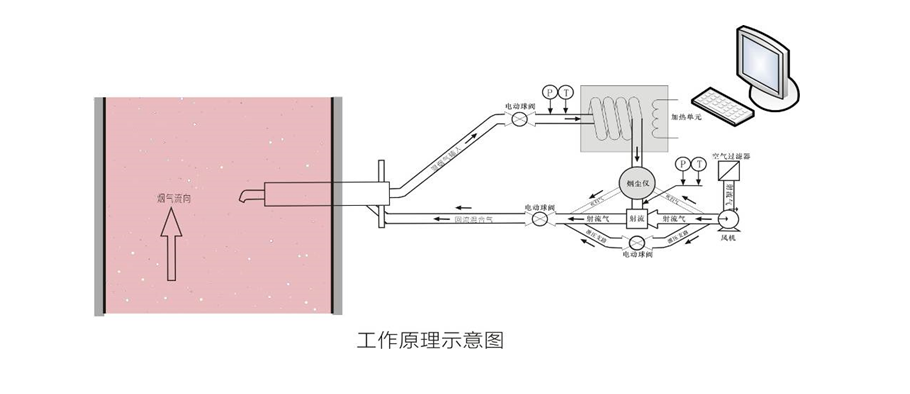

Particulate Matter Monitoring Subsystem:

The LGC-01 system offers exceptional sensitivity and, when paired with a flue gas pretreatment module, reliably measures ultra-low particulate concentrations in moist flue gas. The system is comprised of an emission and receiving unit, along with the pretreatment module. This module includes a sampling probe, jet pump, heating unit, and pressure and temperature control unit, as well as a constant temperature measuring chamber. It extracts sample gas from the flue duct, heats it above its dew point, and then directs it to the measuring chamber. The exhaust gas is returned to the flue duct via the sampling probe. Jet and purging gases are produced by a fan, with the purging gas utilized to clean the optical components, ensuring the system operates reliably over the long term.

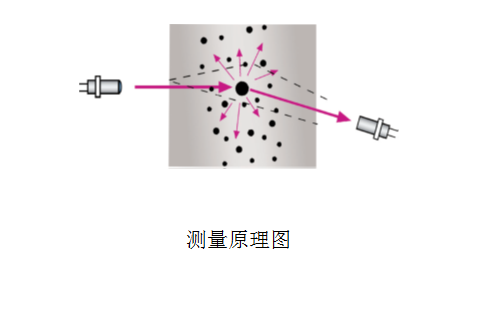

Working Principle Diagram:

The system measures the scattering light intensity of particles based on the principle of forward scattering and outputs the concentration of particulate matter using a specific algorithm. An embedded high-stability laser signal source passes through a temperature-controlled measurement chamber, illuminating the smoke particles. The illuminated smoke particles reflect the laser signal, and the intensity of the reflected light is proportional to the concentration of the particulates. The receiving unit and the emitting unit are positioned at a specific forward scattering angle to capture the scattered light signal, achieving exceptionally high detection sensitivity.

Relevant Certifications: